- Product Catagory

- Contact Us

- Tel:0086 23 8823 9845, Mobile: 0086-135-2739-0908,

- Fax:0086 23 8823 9845

- Contact:Mr. Kevin Dube

sales@fuoo.net

sales@fuoo.net sales@oil-filtration-engineering.com

sales@oil-filtration-engineering.com- Skype

kevinnchiang

kevinnchiang

- Site > Home > Transformer Oil Filtration System > Double-stage Vacuum Transformer Oil Filter machine, Vacuum Oil Filtration Systems, Cable Oil Restoration Machine

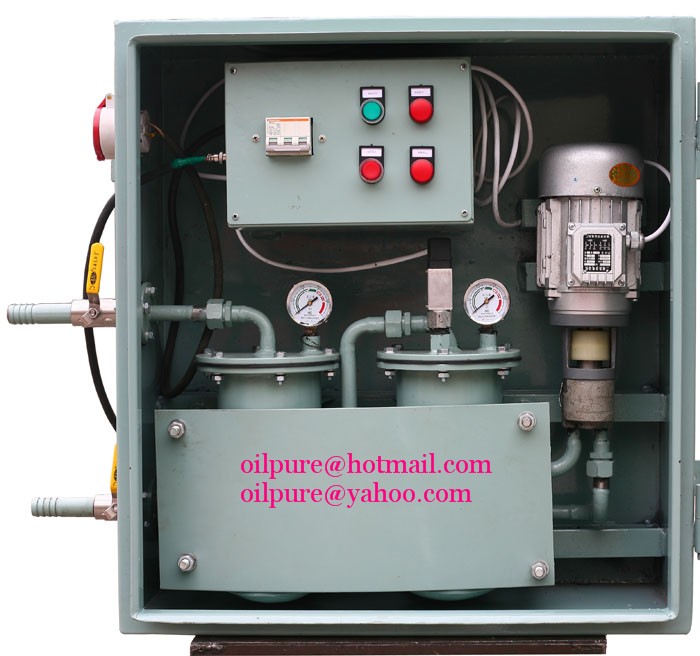

- Product images

- Detailed description

Product Description The TOPS Series Transformer Oil Purification/ Regeneration machine is mainly used to improve the properties of insulation oil. It can remove trace dust, water, gas, particulate matters etc. From the insulating oil effectively and rapidly so as to boost performance of transformers, circuit breakers, mutual inductors, cable and capacitors which have insulation system. TOPS Series specialize in purifying transformer oil, insulating oil of high voltage and super high voltage transformer. Additionally, it is also suitable for treating low viscosity lubrication oil.

Edges of TOPS Series

◆ To remove free, soluble water, carbon, free and dissolved gases and particulate matters, dust from insulating oil, transformer oil, dielectric oil, cable oil effectively and rapidly.

◆ With Vacuum pump and Roots pump.

◆ Enhance the value of breakdown voltage greatly.

◆ Easy handling and maintenance.

◆ Inject oil into the transformers.

◆ Lower maintenance and replacement expenses.

◆ Automatic reverse-washing system will extend the lifetime of filters and improve the performance of the filters.

◆ High performance security system including pressure protection device and automatic temperature controller makes purifier operate safely.

◆ Utilizes coacervation technology, coalescing technology, separating technology and refined purification technology. To remove free, soluble water, carbon, free and dissolved gases and particulate matters from insulating oil effectively and rapidly.

Structure

◆ Dehydration (Degas) System

1, The vacuum chamber has flash tower, which can evaporate the water efficiently. Also it has the spraying nozzle with degassing elements design. The heater, being placed on the vacuum vessel, becomes an evaporator. Thus the flash tower of vacuum vessel is three times more than that of the general vacuum vessel. This innovation can dehydrate and degas effectively and efficiently.

2, The optimal structure of the dehydration (degas) system enlarges the surface area of oil exposed to the vacuum system and extends the flowing distance of the oil in the vacuum system. Thus there has sufficient time to remove the moisture and gas from the oil by vaporization.

◆ Filtering System (particulate matter removal)

1, The filtering materials with variable apertures are made of specialized glass fiber or stainless steel optionally. The sizes of the filtering fiber and aperture dwindle gradually in the different filtering stages. The impurities with different particulate sizes are filtered step by step. The capability of removing particulate matters and impurities is improved greatly by this method.

2, The filtering system has stable and prefect filtering fineness. The filtering fineness has several grades, including 0.5, 1, 2, 3, 5, 6, 10 Micron etc. Oil β>=1000 after filter.

3, The filtering system is equipped with reverse rinse and filth device. It improves the effectiveness of filtering and extends the lifetime of filter awfully.

◆ Oil heating System

1, The unique heater structure heats the oil uniformly.

2, Oil Heater System assures less then 1.0 w/cm2. During the heating process, the deterioration of the oil caused by overheating is avoided.

3, The oil temperature can be adjusted between 20C to 80C. The heater is controlled manually or automatically. The heater will stop automatically when the oil temperature reaches a certain degree.

4, Being installed with safety protection devices, the heating system is secure and reliable. The heater will stop operation automatically when the oil volume of inlet is too low to avoid the damages of the heater.

◆ Electrical Apparatus Controlling System

1, The main components of the electrical apparatus made by Schneider, Siemens and so on ensure the safety of the controlling system.

2, Having several protection systems which will avoid oil ejection, overload and over voltage etc.

◆ Oil-level Controlling System

1, The oil-level floating ball or infrared liquid level automatic controller system are installed in the vacuum vessel to control the oil level so as to avoid the oil being suctioned into vacuum pump in the operation.

2, The new innovation of eliminating froth can avoid the oil being suctioned into vacuum pump.

◆ High quality components

The main components parts of Tongrui products such as vacuum pump, Roots pump, oil pump and electric apparatus are from SIEMENS, LEYBOLD, OMRON, SCHNEIDER, HYDAC, TONGRUI, AMICO etc. It ensures oil filtration systems products high quality and reliability.

◆ Vacuum Pump

Rotary Vane Vacuum Pumps, is a basic equipment used for pumping air from sealed vessels to attain vacuum condition.

The vacuum pumps may be applied singly, or as the backing pump of the other kinds of pumps, such as booster pump, diffusion pump, molecular pump and titanium pump etc. it may be used for vacuum film-plationg, vacuum heat treatment, vacuum ca-sting and also air-extraction of electric tubes, bulbs and thermos flaks. The pump may also be equipped in medical institutions and laboratory.

Capacity:3740L/Min

Ultimate pressure:less than 6*10-2Pa

Rotary speed of pump:450 R/Min

Motor Power: 3Kw

Cooling mode: water cooling, >1L/min

◆ Roots Pump

Roots pumps can be used as boosters combined with backing pump. Of a rotary vane vacuum pump,or a liquid ring vacuum pump. But they can not be used to exhaust No Water-cooking silent running due to specially selected gears Overflow valve which permits the pump to be swiched on at atmospheric pressure and gives shorter evacuation times Standardized ISO connections Smooth running due to dynamically balanced rotor Low operating costs with high pumping speed in the medium-high vacuun range No friction of moving parts in the compression chamber due to even gaps between rotors and housing walls.

Capacity:1250m3/h

Ultimate pressure: 5*10-2Pa

Rotary speed of pump: 2890r/min

Motor Power: 4Kw

Cooling mode: water cooling, >2L/min

Instrumentation options

◆ Foam Level Detector

When there is foam in the tank and foam reaches a certain level (resetable), a signal will be sent to the magnetic valve, the magnetic valve will automatically shut on. The foam will be removed quickly. After removing foam, the magnetic valve will shut off.

◆Digital Vacuum Gauge

Measure Scope: 1.0×105-1.0×10-1PaDisplay Type: Digital

Accuracy: ±1.0%

◆ Digital Hygrometer

Measure Scope: 0—100PPM

Display Type: Digital

Output Singal: one is PPM, the other is temperature.

◆ Digital Flow Meter

Display Type: LCD

Mode: 1) accumulative total value 2) online flow value 3) accumulative total value for each time (reset adjustment)Guarantees & documentation

We warrants the plant supplied under this specification against defects in material and workmanship under normal use and service for a period of sixteen (16) months from date of shipment or twelve (12) months after the start up of the system. Our obligation under this warranty is limited to repairing or furnishing, without change F.O.B. point of manufacture, a similar part to replace any part, which was proven to be defective within wattanty period. We shall not in any event be held responsible for any indirect or consequential damages.Key search words: Vacuum Oil Purifier, Industrial lubricant Oil Filtration, Hydraulic Oil Cleaning, Gear-box Oil Recycling, Compressor Oil Filtering Plant, Coolant Oil Treatment Machine, Diesel Oil Purification, Oil Regeneration, Oil Purifying Plant , Transformer Oil Filtration System, Insulating Oil Treatment Machine, Dielectric Oil Reconditioning Machine, Oil Regeneration, Oil Restoration, Oil Re-processing, Transformer Oil Purification System, Oil Flushing Equipment, Vacuum Oil Dehydration and Degasification Unit

- Related productsMore>>

- Home | About us | Products | Factory View | FAQ | News | Feedback | Contact us |

- Address:No. 5 Hongshi Street, Jiulongpo District, Chongqing, China

- Tel:0086 23 8823 9845, Mobile: 0086-135-2739-0908, Fax:0086 23 8823 9845